ONLINE STORE

ONLINE STORE

© 2023 Usagi no Nedoko Inc. All rights Reserved.

3.8 billion years have passed since the one single life began on Earth. Later, these lives evolved into flowers, fruit and seeds. These lives maintained the life cycles for millions upon millions of generations.

The colors and materials each have their own unique purposes. These intriguing shapes have form unpretentiously with each functional purpose by the hand of Mother Nature.

We offer beautifully preserved plants, exquisitely in the form of a 1.6" x 1.6" x 1.6" (40mm x 40mm x 40mm) acrylic cube.

Sola cubes can be arrange and combine in multiple patterns to inspire sensitivity and learning. Arrange your Sola cubes, observe them intently, and appreciate the wonder or botanical lives.

By observing a small plant carefully, we are able to glimpse a more perfect world.

We express the name “Sola” with the Chinese kanji 宙, which means “universe.” This kanji explains everything we know and don't know, including time and space, with a single character. Sola also has another meaning: “blue sky.” An imaginary world spreads out like the sky before us.

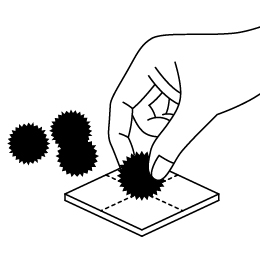

Plants to be encapsulated in a Sola cube are sorted by size and shape. To prevent the release of dust and dirt when they are encapsulated, plant materials are also cleaned.

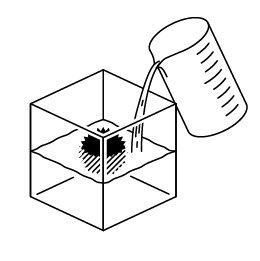

Liquid acrylic is poured into a mold which is slightly larger than the Sola cube. The dried plant is carefully inserted when the liquid hardens to a gel.

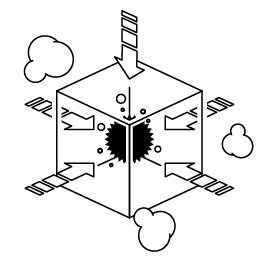

Additional liquid acrylic is then poured into the mold. The mold is placed into a vacuum kiln, then pressurized to force out any air bubbles. The product then undergoes a heat treatment. This stabilizes the binding of the acrylic, and ensures the cube is durable and long lasting.

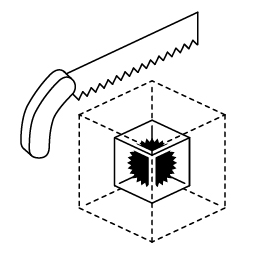

The cube is cut to precisely 1.6in(40mm) on each side, then planed. The corners are rounded and smoothed at the end of this step.

The surface of the cube is polished until it is shiny, and a clean, glossy finish is achieved.

* The manufacturing process and resin used in polishing is adjusted, depending on the variety of plant to be set inside the cube.

BACK TO TOP